Evidence of the Hijack of Malaysian Airways Flight MH370 using the

Boeing-Honeywell Uninterruptable Autopilot

Introduction

Introduction

The aim of this research document is to prove the technology, deployment and use of the BoeingHoneywell

Uninterruptable Autopilot (BHUAP) in the hijacking of Malaysian Airlines Flight 370 in

the early hours of March the 8th 2014, whilst en-route from Kuala Lumpur in Malaysia to Beijing,

China. As Boeing has already admitted to such technology having been installed on its aircraft,

this paper will investigate the B777 flight systems and the avionics technology supplied by Honeywell

and related companies to expose the history of the BHUAP and how it operates.

Using publicly available information, the argument will take five principal forms:

Section 1

. Evidence by way of Media Reporting as to the existence and deployment of the BoeingHoneywell

Uninterruptable Autopilot and the Boeing and Honeywell Antihijack Patents

Section 2

. Black Text - Evidence by way of existing remote flight technology capable of the task,

developed by Boeing, Honeywell and associated avionics and software companies

.Blue Text - Evidence by way of patents filed and approved to accomplish the task by Boeing,

Honeywell and associated patent holders

. Red Text – Evidence by way of a combined analysis based on the patents and the as-installed

technology aboard the B777-2H6ER with emphasis on how BHUAP works within these

systems

Section 3

. Evidence by way of analysis of the flight path and system disruption of the B777-2H6ER

flight MH370

To open, Honeywell filed for a patent in 2002 US20030030581A1 (1) “Secure aircraft

communications addressing and reporting system (ACARS)” - A method and apparatus that permit

military aircraft operators to use the civilian Aircraft Addressing and Reporting System (ACARS)

technology while ensuring data security. This invention relates to work done as part of the Dual Use

Science and Technology program under US Air Force Research Laboratory Agreement No.

F33615-01-21808.

The patent goes on to say “With the increase in automation, airlines, military, and civil aviation

organizations are relying on ACARS for air traffic and operational control. Unfortunately,

automated information exchange between airborne and ground computers also increases the

vulnerability of the system and may severely impact the safety of a flight or an air space.”

“ACARS messages are transferred over open RF channels in human readable forms. Low cost, COTS

equipment enables anyone to monitor and process ACARS messages. It is possible to determine

aircraft type, condition, position, projected track, cargo content and operational details of the flight by

analyzing ACARS messages. Aircraft operators would like to protect this information to maintain

competitive advantage, to ensure safety of flight and to reduce operational liability.

There was a clear concern by the US military about unencrypted communication with modern

aircraft computer systems, not from a commercial point of view, but from something that could

“severely impact the safety of a flight or an air space”. We will explore what that may have been.

Details of the Boeing 777

Servicing Flight MH370

On the 8th March 2014 Flight MH370 was serviced by a Boeing 777-2H6ER (ER stands for Extended

Range and H6 is Malaysian Airlines designated customer code) with serial number 28420, registration

9M-MRO. (2) The 404th Boeing 777 produced since June 1997, it first flew on 14th May 2002, and

was delivered new to Malaysia Airlines on 31st May 2002. (2) The aircraft was powered by two

Rolls-Royce Trent 892 engines, and configured to carry 282 passengers and 10 crew. 9M-MRO had

accumulated 53,460 hours and 7,525 cycles in service. On the night of the hijack there were 239

people on board.

Section 1

Media Reports Regarding the BHUAP

Reporting on The Boeing Company

In response to Civil Case 3:07-cv-24 at District Court, District of North Dakota on 27 February, 2007

(Case entitled FIELD MCCONNELL v. ALPA and BOEING), Boeing issued a statement to

reporters documented on the 3rd March 2007 admitting to the existence of the Boeing

Uninterruptable Autopilot. This was extensively reported. For posterity Appendix 1 – London

Evening Standard & The Daily Mail (3)(4) contains a dual article run on the 3rd March 2007 relating

to Boeing’s Uninterruptable Autopilot patent and Boeings statements confirming it. The article

opens with the lines “The mechanism is designed to make it impossible to crash the aircraft into air or

land targets - and enable the plane to be flown by remote control from the ground in the event of an

emergency. Scientists at aircraft giant Boeing are testing the tamper-proof autopilot system which

uses state-of-the-art computer and satellite technology“.

The Boeing patent is US7142971B2, (5) 19 Feb 2003 “System and method for automatically

controlling a path of travel of a vehicle” where it is described as “The method and system for

automatically controlling a path of travel of a vehicle include engaging an automatic control system

when the security of the on-board controls is jeopardized. Engagement may be automatic or manual

from inside the vehicle or remotely via a communication link. Any on-board capability to supersede

the automatic control system may then be disabled by disconnecting the on-board controls and/or

providing uninterruptible power to the automatic control system via a path that does not include the

on-board accessible power control element(s). The operation of the vehicle is then controlled via the

processing element of the automatic control system. The control commands may be received from a

remote location and/or from predetermined control commands that are stored on-board the vehicle.”

Appendix 2 – Homeland Security News Wire (6) run on the 4th December 2006 and discusses the

technology further: “Boeing’s is, of course, not the first autopilot technology in existence, but this one

has been designed with counter terrorism first and foremost in mind. Not only is it “uninterruptible”

— so that even a tortured pilot cannot turn it off — but it can be activated remotely via radio or

satellite by government agencies. The system might even include sensors on the cockpit door that

activate the autopilot if a certain amount of force is used against it. “There is a need for a technique

that ensures the continuation of the desired path of travel of a vehicle by removing any type of human

decision process that may be influenced by the circumstances of the situation, including threats or

further violence on-board the vehicle,” the patent application explains. To make it fully independent,

the system also has its own power supply, independent of the aircraft’s circuit breakers.”

Whilst reporting extensively on the disappearance of MH370, CNN’s Brian Todd discussed the idea

during live coverage on the 29th March 2014 (7). During the coverage Todd remarked: “A lost signal,

a vanished plane and on the ground a feeling of complete helplessness. But an idea has circulated to

put auto pilot on passenger planes on remote control in stress situations. . In 2004 Boeing applied for

a patent for a system referred to as uninterruptible autopilot.”

And later, “Has Boeing advanced this idea from ten years ago? Is the company still testing it out? Or

has it scrapped the idea entirely? We tried multiple times to get information from Boeing on this

project. The company wouldn't speak to us about it.”

In Appendix 3 – Excerpt from “The Terror Conspiracy Revisited” (8), Jim Marrs writes about the

Boeing Uninterruptable Autopilot existing in 1995:

“Former German Defense Minister Andreas von Bülow, in a January 13, 2002, interview with the

newspaper Tagesspiegel, in speaking about the 9/11 attacks, noted, “There is also the theory of one

British flight engineer [and] according to this, the steering of the planes was perhaps taken out of the

pilots’ hands from outside.

The Americans had developed a method in the 1970's whereby they could rescue hijacked planes by

intervening into the computer piloting [the electronic flight system]. This theory says this technique

was abused in this case.” Von Bülow could well have knowledge of this technology as several

researchers and websites have stated that Lufthansa, Germany’s national airline, was aware of the

possibility of electronic capture and had quietly stripped the flight control systems out of its

American-built jetliners in the early 1990's.

The British flight engineer Von Bülow mentioned is Joe Vialls, a journalist, author, private

investigator, and a former member of the Society of Licensed Aeronautical Engineers and

Technologists based in London.“

Von Bülow was referring to the 23rd of October 1970, Tool O K Incorporated patent Autopilot

system controlling entry of a craft into forbidden zones US 3749335 A (9) – “In combination with

the autopilot system of an aircraft, an on board control system, inaccessible to the pilot, responds

to ground transmitted or on board computed geographical position signals to restrict pilot heading

or descent maneuvers when the aircraft enters a forbidden geographical zone.” The technology used

to accomplish this patent was further enhanced as navigational aids and digital flight technology was perfected,

resulting in the BHUAP.

In 2001, Joe Vialls’ article “France, Russia, Germany Responsible for 9-11” (10) discussed the

Boeing Uninterruptable Autopilot. Vialls research has credibility as he was writing about it some 5

years before the patent was made public in 2006.

“During early 1995, Boeing sales experienced an unconnected but serious internal problem in

Europe, though the details were never made public. The German flag carrier Lufthansa discovered

that its new Boeing 747-400 aircraft had been fitted with flight directors [auto-pilots] that were

vulnerable to American remote-control, ostensibly designed to “recover” hijacked aircraft whether

the hijackers wanted to be recovered or not. Lufthansa was not informed about this “free extra” in

advance, and was furious that its sovereign aircraft might be covertly “rescued” by America, without

the knowledge or permission of the German Government.

In a mammoth operation rumored to cost in excess of $800 million, Lufthansa stripped every flight

director out of every Boeing in its fleet, replacing them in total with German systems programmed by

the Luftwaffe [German Air Force]. According to a member of the German internal security service in

Frankfurt during October 1996, all Lufthansa aircraft had by that date been secured, rendering them

invulnerable to remote flight director commands transmitted by any and all American authorities.

Under the new intelligence protocols, Russia and France were made aware of these flight director

risks.”

Reporting on Honeywell International

As early as 2005, Boeing’s preferred avionics supplier, Honeywell, was reported by Stephen Trimble

Appendix 4 – Flight International Magazine (11), to be talking to both Boeing and Airbus about

fitting a device aimed at preventing a 9/11-style hijack.

Trimble reports “Honeywell’s marketing strategy for the “automatic” or “assisted” recovery system

is focused on gaining acceptance with the Airbus A350 and the Boeing 787, with the former seen as

the more natural candidate given Boeing’s philosophical objections to any system that overrides the

pilot’s control of the aircraft.”

In fact, Honeywell was cited in Pilot Authority Denial patented technology as far back as 1970.

The Tool O K Incorporated patent US 2953329 A referred to in Von Bülow’s comments ‘American

system designed to rescue hijacked jets’ was based on the Honeywell Regulator Company, 1956

Patent US 2953329 A , (12) Automatic control apparatus for aircraft. A patent cannot cite

another patent unless there is agreement between the two parties that the previously patented

technology can be altered. Honeywell and Tool OK Incorporated would have discussed and agreed to

this even prior to 1970.

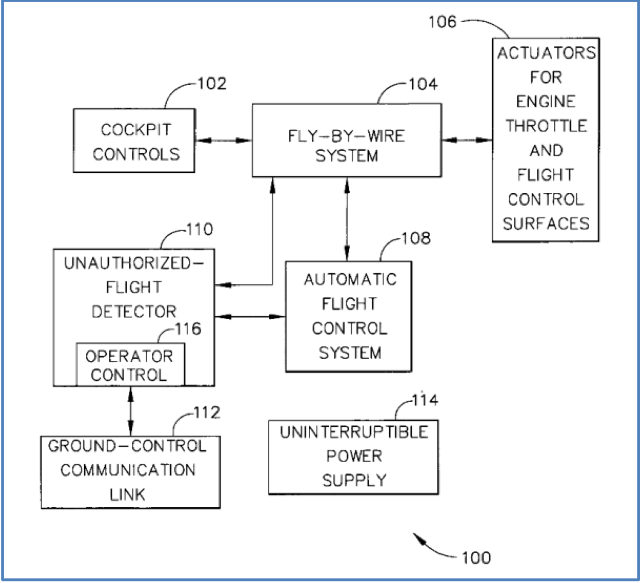

On the 16th April 2003, Honeywell filed patent US7475851B2 (13) “Method and apparatus for

preventing an unauthorized flight of an aircraft” describing “A fly-by-wire (FBW) system (104) is

coupled to cockpit controls (102) of an aircraft for controlling the aircraft, and an automatic flight

control system (AFCS) (108) is coupled to the FBW system for maintaining the aircraft in stable

flight. An unauthorized-flight detector (110) is coupled to the FBW system and coupled to the AFCS,

and is arranged to carry out (306) a transfer of control of the FBW system from the cockpit controls

to the AFCS, in response to a predetermined event.”

In a 2003 Wired News Report (14) also found in Appendix 5 – Wired News it was reported:

“Airbus and Honeywell are close to perfecting technology that takes control of airplanes to prevent

them from crashing into obstacles, The Wall Street Journal reports. When audible warnings from

crash-avoidance systems are ignored, the system overrides actions by the pilot and takes evasive maneuvers, the newspaper said.

The system would link crash-warning devices, already common on airliners, with cockpit computers

that could automate flying to prevent collisions, executives from Honeywell (HON) said. Tests have shown "promising results," but the idea of completely turning an airplane's controls over to a

computer could make people nervous.

European airplane maker Airbus, owned by EADS (EAD) and Britain's BAE Systems, has been

working on the project with Honeywell for years, although development sped up after the Sept. 11,

2001 hijacking attacks. The team may have beaten NASA, the Pentagon and Boeing to the finish

line.”

The quote from Airbus clearly reveals that Pilot Authority Denial systems were ALREADY BEING

DEVELOPED by Honeywell prior to 2001, and as Vialls claims, since the introduction of the Boeing/Honeywell

AIMS-1 Flight Management System in 1995. Now it was Airbus’ turn.

The Wall Street Journal article cited in the Wired News Report article can be found in Appendix 6 –

The Wall Street Journal (2003). It goes further to explain a system very closely resembling BHUAP:

“Airbus, the big European jet maker, and Honeywell, an aerospace and industrial manufacturer in

Morris Township, N.J., have been working on the so-called Auto-Avoid principle for years. That effort

accelerated after the Sept. 11 attacks and is particularly timely in light of recent government

warnings of possibly more suicide hijackings of planes. The National Aeronautics and Space

Administration, the Pentagon and rival jet maker Boeing Co. are all pursuing their own research into

crash-prevention devices, but none are believed to be as far along as Honeywell and Airbus.” (15)

This report will later show that Boeing had in fact beaten Airbus in the implementation of the BHUAP

by 8 years at the time that The Wall Street article was written.

“Taking that principle to a new level, the latest technology allows an aircraft's computers to instantly

seize control when such audible warnings are ignored, or when a plane tries to enter computer generated

"no-fly zones" around skyscrapers, monuments and government buildings. The system

would override pilot commands if necessary and, on its own, take evasive action. "If a pilot veers off

course" substantially for any reason and fails to respond to repeated warnings, "the airplane will

take over and fly" the correct path, says Robert Johnson, chief of Honeywell's aerospace unit.”

This is exactly the BHUAP modus operandi that this report will allege took MH370, heard from the

horse’s mouth. This matches the 1970’s patent involving Honeywell’s Flight Management System

(FMS) and matches the 2002 & 2003 patents applied for, and granted to Honeywell and Boeing.

Embedded into Boeing in 1995 through the Honeywell FMS, and subsequently finding its way into

Malaysian Airlines flight MH370.

“Eventually they [Pilots] may embrace the Auto-Avoid system, but "only if there is some way it can be

turned off by the crew," said John Cox, air-safety chairman of the Air Line Pilots Association.

But allowing crew members to disable it would defeat one of the main purposes, to thwart hijackers.

Since few other industry initiatives boast both safety and security components, the system is a natural

for continued funding.” (15)

Section 2 –

Technology, Patents and As

Installed Systems on MH370

A Forward to the Boeing

Honeywell Uninterruptable

Autopilot (BHUAP)

As we strip down the 777 avionics architecture it is crucial to note that the B777 operates through a

COMPLEX, DIGITALLY INTEGRATED FLIGHT MANAGEMENT SYSTEM. There are many

contributors to the B777 avionics. The autopilot for example was made and programmed by

Rockwell Collins, however the autopilot is only a slave to further control systems. The Boeing

Uninterruptable Autopilot IS ROOTED IN THE SOFTWARE CODING that governs how the Flight

Management System operates, in particular the Unauthorized Flight Detector routines, not in one

particular slave system such as the autopilot.

To understand the “UNINTERRUPTABLE” is to understand how the SOFTWARE

REMOVES OTHER SLAVE SYSTEMS to ISOLATE the autopilot from on-board Pilot

Authority without rendering the aircraft vulnerable to system failure through loss of

redundancy (ie. loss of safe autopilot navigation and control).

The Development of Boeing and

Honeywell Technology that was

Installed

on MH370 at the

Time of the Disappearance.

Despite Boeing’s 2007 admission as to their intention to install the Boeing Uninterruptable Autopilot

on all civil aircraft by 2010, let us have a look at how long such technology has been in existence, so

as to verify Joe Valis’ claims that this technology had been installed in Boeing aircraft through

the Honeywell Flight Management System since 1995.

As Honeywell is the preferred avionics and flight management systems supplier to Boeing we will

concentrate on the contributions that these industry leaders have made in the development of the

necessary Remote Flight Technology specifically needed for the BHUAP.

1954 – Boeing Remote Control

Unmanned Aerial Vehicles

Boeing was working with NASA and other companies and agencies after the WW2 to advance longdistance

remote control flight technology. The Department of Defence had plans for a fleet of

remotely piloted intercontinental bombers.

Importantly, one aim of the project was to create an effective method and means by which the flight

of one separately power driven airplane may be controlled directly pilot in a separate airplane may

accompany and control an aerodyne, such as a large airplane on a long distance bombing mission or

the like without subjecting himself to the intense vulnerability usually encountered.

It is alleged that MH370 was under the influence of such technology (BHUAP) undertaken by an

AWACS related to the Cope Tiger joint exercises being conducted in the Gulf of Thailand at the time.

Boeing’s patent for this technology was filed in 1954 as US2883125 A (16) conspicuously named

“Composite Aircraft - This invention relates to a method and means for controlling aircraft flight, and

more particularly the flight of a pilotless airplane… The guidance of aerodynes, such as pilotless

airplanes by remote control through radio means and the like has reached an advanced stage but is

not well suited for long distance flights…”.

1956 - Boeing-Honeywell Autopilots

The history of autopilots date back to World War 1, developed by Sperry Corporation in 1912 and

patented in 1916 as US 1415003 A (17) Automatic pilot for airplanes. “The autopilot connected a gyroscopic heading indicator and attitude indicator to hydraulically operated elevators and rudder… It

permitted the aircraft to fly straight and level on a compass course without a pilot's attention, greatly

reducing the pilot's workload.”

Eventually in 1986, Sperry Flight Systems was absorbed into Honeywell Inc however Honeywell’s first autopilot patent was US 2953329 A (18) Automatic control apparatus for aircraft, filed in 1956.

Honeywell is today’s leading manufacturer of avionics equipment. “Honeywell Aerospace began in 1914. Over nearly a century, through various acquisitions, mergers and name changes, Honeywell Aerospace combined legacy companies Sperry, Bendix, Garrett AiResearch, Pioneer, Lycoming, Grimes, King Radio (Company) and Allied Signal. Garrett Corporation also acquired Aero Engineering Inc., Aero Sales Engineering, Ltd. and Air Cruisers Company in 1954. Following the death of its founder John Cliff Garrett in 1963, Garrett Corporation merged with Signal Oil & Gas Company to avoid a hostile takeover by Curtiss-Wright, forming The Signal Companies. In 1982 Allied Corporation acquired Bendix Aerospace after coming in late in a protracted fight involving Bendix, Martin Marietta, and United Technologies. In 1985 The Signal Companies merged with Allied Corporation forming Allied-Signal Inc. Allied-Signal (later renamed to Honeywell International in 1999) now includes [what was (in 1986) called] Honeywell Inc., and in 1986 Honeywell Inc. acquired Sperry Aerospace for $1.025 billion. Allied-Signal acquired the Lycoming Turbine Engine Division of Textron in 1994, and Grimes in 1997. Allied-Signal acquired Honeywell in 1999, and changed the name of the resulting company to Honeywell International.” (19)

As you can imagine this has given Honeywell and subsequently Boeing a large pool of patents.

It is important to re-iterate here that BHUAP has two components, the hardware and the software. Both these components lie within the scope of each patent. The MH370 B777-200 contained an AFDS-770 Autopilot Flight Director System manufactured by Rockwell Collins. (20) The autopilot is a necessary component for BHUAP to operate however as previously stated it is a slave system to the software that directs aircraft navigation. We can therefore rule out the autopilot system as being individually capable of remote hijack. Honeywell worked closely with Boeing and additional programmer Marconi Systems to develop the B777 BHUAP software.

Software will be covered later however one can at this stage note: “In addition to avionics, in 1970, Honeywell merged its computer business with General Electric's to form Honeywell Information Systems, which performed well in mainframe markets. In 1986, the personal computer emerged and the company formed Honeywell Bull, a global joint venture with Compagnie des Machines Bull of France and NEC Corporation of Japan. Its ownership level was gradually decreased until, in 1991, Honeywell was no longer in the computer business. The company’s digital computer knowledge was then applied to its traditional field of automation control, integrating sensors, and activators.” (19)

It goes on to say: “Although purportedly terminated on January 28, 1999, it was reported in April

2003 that the RQ-3 [Dark Star] was still in development as a black project. The size and capabilities

were reported to have increased somewhat. It was further alleged that the first such example had been

used in the 2003 invasion of Iraq. There has been no independent confirmation.” (27)

It goes on to say: “Although purportedly terminated on January 28, 1999, it was reported in April

2003 that the RQ-3 [Dark Star] was still in development as a black project. The size and capabilities

were reported to have increased somewhat. It was further alleged that the first such example had been

used in the 2003 invasion of Iraq. There has been no independent confirmation.” (27)

Eventually in 1986, Sperry Flight Systems was absorbed into Honeywell Inc however Honeywell’s first autopilot patent was US 2953329 A (18) Automatic control apparatus for aircraft, filed in 1956.

Honeywell is today’s leading manufacturer of avionics equipment. “Honeywell Aerospace began in 1914. Over nearly a century, through various acquisitions, mergers and name changes, Honeywell Aerospace combined legacy companies Sperry, Bendix, Garrett AiResearch, Pioneer, Lycoming, Grimes, King Radio (Company) and Allied Signal. Garrett Corporation also acquired Aero Engineering Inc., Aero Sales Engineering, Ltd. and Air Cruisers Company in 1954. Following the death of its founder John Cliff Garrett in 1963, Garrett Corporation merged with Signal Oil & Gas Company to avoid a hostile takeover by Curtiss-Wright, forming The Signal Companies. In 1982 Allied Corporation acquired Bendix Aerospace after coming in late in a protracted fight involving Bendix, Martin Marietta, and United Technologies. In 1985 The Signal Companies merged with Allied Corporation forming Allied-Signal Inc. Allied-Signal (later renamed to Honeywell International in 1999) now includes [what was (in 1986) called] Honeywell Inc., and in 1986 Honeywell Inc. acquired Sperry Aerospace for $1.025 billion. Allied-Signal acquired the Lycoming Turbine Engine Division of Textron in 1994, and Grimes in 1997. Allied-Signal acquired Honeywell in 1999, and changed the name of the resulting company to Honeywell International.” (19)

As you can imagine this has given Honeywell and subsequently Boeing a large pool of patents.

It is important to re-iterate here that BHUAP has two components, the hardware and the software. Both these components lie within the scope of each patent. The MH370 B777-200 contained an AFDS-770 Autopilot Flight Director System manufactured by Rockwell Collins. (20) The autopilot is a necessary component for BHUAP to operate however as previously stated it is a slave system to the software that directs aircraft navigation. We can therefore rule out the autopilot system as being individually capable of remote hijack. Honeywell worked closely with Boeing and additional programmer Marconi Systems to develop the B777 BHUAP software.

Software will be covered later however one can at this stage note: “In addition to avionics, in 1970, Honeywell merged its computer business with General Electric's to form Honeywell Information Systems, which performed well in mainframe markets. In 1986, the personal computer emerged and the company formed Honeywell Bull, a global joint venture with Compagnie des Machines Bull of France and NEC Corporation of Japan. Its ownership level was gradually decreased until, in 1991, Honeywell was no longer in the computer business. The company’s digital computer knowledge was then applied to its traditional field of automation control, integrating sensors, and activators.” (19)

1958 - The Ring Laser Gyroscope

Sperry was manufacturing gyroscopes from around the turn of the century. The gyroscope is an

integral part of any navigational and autopilot system. Honeywell invented and perfected the Ring

Laser Gyroscope which uses fluctuations in the intensity of laser beams to determine acceleration on

the three principal axes.

Honeywell states: “An early landmark commercial avionics technology was the ring laser gyroscope

(RLG), which was developed in 1958. Honeywell supported the "long and painful" development

process, but was rewarded by the 1970s. Honeywell also developed the Laser Inertial Navigation

system. Both RLG and the Laser Inertial System help navigation and automatic flight control systems

measure altitude, position, velocity and rotation. By 1991, 45,000 RLG devices were sold” (19)

First patented in 1965, Honeywell’s RLG is an integral part of the B777 Air Data Internal Reference

Unit. These units are integral to any modern autopilot system, providing accurate acceleration data for

improved navigation and flight control.

Perfection of the RLG since 1991 enabled Honeywell to replace the QRS11 Gyrochip in its newer

inertia systems facilitating the ability to export Flight Management Systems to a broader set of clients.

The QRS11 is a military grade solid state gyro used mainly in missile applications and is subject to

stringent US export restrictions.

1975 - Software and Programmability

of Avionics Systems

Honeywell was working closely with NASA, contributing to both the hardware and software

development necessary to facilitate the Glass Cockpit into Fly-by-Wire aircraft.

Ada 83 and Ada 95 Programming Language initiated by the Department of Defense in the latter

1970’s. “Ada 95 is a comprehensive high-level programming language especially suited for the

professional development of large or critical programs for which correctness and robustness are

major considerations. Ada 95 is a direct descendant of, and highly compatible with, Ada 83, which

was originally sponsored by the U.S. Department of Defense for use in the embedded system

application area. Ada 83 became an ANSI standard in 1983 and an ISO standard in 1987.” (21)

Honeywell worked with Marconi Systems in the early 1980’s to develop the FMS software for the

Boeing 757 and 767, and with Reflectone Inc on the A310. Reflectone Inc later became CAE Inc, and

Boeing now works directly with them to develop flight simulators for training purposes.

Whilst today programming languages have evolved further to incorporate the ARINC data protocol

for fly-by-wire aircraft, the necessary functions and robustness necessary for FAA certification of the

Honeywell Flight Management System using the Ada96 Language was obtained by 1984 which

included accreditation of the software.

1980 - The Glass Cockpit

Revolution in Avionics

“A glass cockpit is an aircraft cockpit that features electronic (digital) instrument displays, typically

large LCD screens, rather than the traditional style of analogue dials and gauges. While a

traditional cockpit relies on numerous mechanical gauges to display information, a glass cockpit uses

several displays driven by flight management systems (programmable computers), that can be

adjusted to display flight information as needed. This simplifies aircraft operation and navigation and

allows pilots to focus only on the most pertinent information. They are also popular with airline

companies as they usually eliminate the need for a flight engineer, saving costs.

As aircraft displays have modernized, the sensors that feed them have modernized as well. Traditional

gyroscopic flight instruments have been replaced by electronic Attitude and Heading Reference

Systems (AHRS) and Air Data Computers (ADCs), improving reliability and reducing cost and

maintenance. GPS receivers are usually integrated into glass cockpits. In the latter 1970’s, NASA

conducted research with Honeywell, Boeing, McDonnel-Douglass and others on displays that could

process the raw aircraft system and flight data into an integrated, easily understood picture of the

flight situation, culminating in a series of flights demonstrating a full glass cockpit system. The

success of the NASA-led glass cockpit work is reflected in the total acceptance of electronic flight

displays beginning with the introduction of the MD-80 in 1979.

Early glass cockpits (found in the McDonnell Douglas MD-80/90, Boeing 737 Classic, 757 and 767-

200/-300, and in the Airbus A300-600 and A310) used Electronic Flight Instrument Systems (EFIS) to

display attitude and navigational information only, with traditional mechanical gauges retained for

airspeed, altitude, vertical speed, and engine performance. Later glass cockpits, found in the Boeing

737NG, 747-400, 767-400, 777, A320 and later Airbuses, Ilyushin Il-96 and Tupolev Tu-204 have

completely replaced the mechanical gauges and warning lights in previous generations of aircraft,

although they still retain some analogue instruments as backups in case the EFIS displays

malfunction.” (22)

By 1984 the FAA had approved Boeing-Honeywell’s digital avionics and flight management systems

for use in civil aircraft such as the Boeing 757, 767 and the Airbus A310, and in 1981 had authorised

the reduction of the minimum flight crew number to 2, eliminating the flight engineer. Specifically,

the Honeywell FMS certification test involved a 19 hour flight in a Boeing Seahawks 747 made in

1984 with the FMS programmed using NASA’s ORACLS program developed at the Langley

Research Facility. (23)

1980-1999 –Remote Control Technology:

The Boeing Dark Star High

Altitude

Unmanned Aerial Vehicle

Using the knowledge gained from the last 30 years of military research and development with

NASA under the Defence Advanced Research Projects Agency (24), Boeing, Honeywell and

Lockheed Martin joined forces to compete against Northrop Grumman to develop an Unmanned

Aerial Vehicle system for the US Defence Advanced Research Projects Agency (DARPA).

The concept of aircraft-based UAV’s first became a reality in 1915 where they were used as aerial

targets. Follow this link(25) for a fuller history of UAV’s.

“In 1994, Boeing teamed with Lockheed Martin again to design and build a stealthy, unmanned

reconnaissance plane called DarkStar for the U.S. Department of Defence Tier III Minus program.

Boeing applied its expertise in unmanned aerial vehicles (UAV), gained over three decades of UAV

experience, to develop the Dark Star's wings and integrated avionics.” (26) See Wikipedia, Dark Star (27)

On the 29th March, 1996 the Dark Star made its fully autonomous maiden flight. Boeing describes

the Dark Star’s technology:

“The DarkStar was fully autonomous: it could take off, fly to its target, operate its sensors,

transmit information, return and land without human intervention.” (26) Wikipedia states:

“Human operators, however, could change the Dark Star's flight plan and sensor

orientation through radio or satellite relay.” (27)

It goes on to say: “Although purportedly terminated on January 28, 1999, it was reported in April

2003 that the RQ-3 [Dark Star] was still in development as a black project. The size and capabilities

were reported to have increased somewhat. It was further alleged that the first such example had been

used in the 2003 invasion of Iraq. There has been no independent confirmation.” (27)

It goes on to say: “Although purportedly terminated on January 28, 1999, it was reported in April

2003 that the RQ-3 [Dark Star] was still in development as a black project. The size and capabilities

were reported to have increased somewhat. It was further alleged that the first such example had been

used in the 2003 invasion of Iraq. There has been no independent confirmation.” (27)

Although the unstable air frame finished off Dark Star, the resulting BHUAP remote control software

and avionics were successful. This facilitated a continuation of the black project and also saw the

software incorporated into the Honeywell Pegasus Flight Management System in 1980, released in

1984, forming the FMS for the B757, B767 and the A320.

1980 – Boeing-Honeywell B757

& B767 Flight Management Systems

Digital fly-by-wire aircraft and the glass cockpit systems are essentially software driven. Drawing on

their past experience in developing the flight management systems for the Apollo and Dark Star programs, both Boeing and Honeywell were the main driving force behind the introduction of digital

autopilot technology into the civil aviation sector. Honeywell’s original flier for the first FMS to offer

complete en-route optimisation of a flight path can be found in Appendix 7.

Honeywell’s 1984 patent EP0186965A1 (28) describes a “Digital fail operational automatic

flight control system utilizing redundant dissimilar data processing” which formed the basis

of the Flight Management System, augmented with 1985 patent US4787041A (29) “Data

control system for digital automatic flight control system channel with plural dissimilar data

processing”.

Honeywell’s 1986 patent US4760530A (30) “Flight management system providing

minimum total cost” describes “the invention relating to Flight Management Systems (FMS)

providing minimum total cost flight profiles particularly with respect to accounting for arrival

error cost functions.”

Boeing’s 1995 patent US5842142A (31) “Least time alternate destination planner” which is

“An alternate destination planner for searching a navigation database in an aircraft and

identifying a plurality of alternate destinations at which the aircraft can land in the event of an

emergency. For each identified alternate destination, the alternate destination planner calculates an

estimated time of arrival (ETA) and an amount of fuel remaining upon arrival at the destination. The

calculation of the ETA and the remaining fuel is based on user-modifiable parameters of aircraft

speed, aircraft altitude, wind direction and speed, outside air temperature, and the type of routing the

aircraft will follow from a diversion point to the alternate destination. The plurality of alternate

destinations are displayed to a pilot of the aircraft according to the ETA to each alternate destination,

with the closest alternate destination by time listed first. The plurality of alternate destinations are also

displayed to the pilot on a map of the surrounding region that is provided to the pilot on a navigation

display. A pilot may select and divert to one of the plurality of alternate destinations using a minimal

number of keystrokes on a control display unit.”

BHUAP being built into the software as an “emergency situation” would hardly stretch the truth. This

would invoke the Alternative Destination Planner to divert to an airfield that was capable of resolving

a hijack incident and where commercial interests and the public were kept safe, such as a military

base.

A fuller explanation of the Flight Management System is necessary here to explain the origins of

some key BHUAP features, such as the introduction of digital avionics and flight route planning,

satellite communications and satellite navigation.

In the Q2-2009 of Boeing’s Aero Magazine, (32) Boeing sums up the development of the FMS as

follows:

“Performance Based Navigation is a concept used to describe navigation performance along a route,

procedure, or airspace within the bounds of which the airplane must operate. For transport airplanes,

it typically is specified in terms of required navigation performance (RNP). The PBN concept defines

navigation performance in terms of accuracy, integrity, availability, continuity, and functionality.

These operations provide a basis for designing and implementing automated flight paths that will

facilitate airspace design, terminal area procedure design, traffic flow capacity, and improved access to runways (more information about PBN can be found in AERO second-quarter 2008). The PBN

concept is made possible largely by advances in the capabilities of airplane FMS.”

Air Navigation Tools

Leading Up to the FMS

In the 1940's, the introduction of a radio-magnetic indicator or dual-bearing distance-heading

indicator facilitated the use of ground-based navaids, including the very-high-frequency omnidirectional

range (VOR) navigation system and distance measuring equipment (DME). VORs came

into wide use in the 1950s and quickly became the preferred navigation radio aid for flying airways

and instrument approaches. VOR and DME provided the framework for a permanent network of low altitude

victor airways (e.g., V-4) and high-altitude jet routes (e.g., J-2), which are still in place

today.

Long-range navigation over remote and oceanic areas, where navigation radio transmitters did not

exist, was originally accomplished by dead reckoning and celestial navigation. The introduction of the

inertial navigation system (INS) on airplanes facilitated long-range capability by providing a

continuous calculation and display of the airplane’s position. Flight crews could enter waypoints and

the INS would calculate heading, distance, and estimated time of arrival to the respective way point.

Boeing’s initial entry into this arena was represented by the implementation of the early Sperry (now

Honeywell) automatic navigation systems on the 727, 707, and 747-100. During this same time,

Collins produced the AINS-70, an area navigation (RNAV) computer on the DC-10. Each of these

steps reduced the amount of interpretation by the flight crew by presenting more specific indications

of airplane positional and situational status. Even so, the reliance on the flight crew to manually

interpret and integrate flight information still provided opportunities for operational errors. (32)

The First Integrated Flight

Management Computer

When Boeing began work on the 767 airplane program in the late 1970's, the company created a flight

deck technology group with engineers dedicated to the development of the flight management

computer (FMC) and the control display unit (CDU). Boeing merged previous designs of the

performance management computer and the navigation computer into a single FMC that

integrated many functions beyond navigation and performance operations. The company used

experience gained from Boeing’s other research projects to develop advanced implementations of

performance management functions and navigation into a single FMC. The new FMC system was

envisioned as the heart of an airplane’s flight planning and navigation function. (32)

Figure 2: 757/767 FMC CDU

One of the first implementations of an FMC CDU was designed for the 757 and 767 in the early 1980's.

While Boeing [and Honeywell] was continuing work on new commercial airplane navigation systems

for the new “glass” flight decks, a debate was under way among the airlines about the need for a

dedicated flight engineer crewmember. In July 1981, an industry task force determined that two-crew

operation was no less safe than three-crew operation. This decision would have a profound effect on

the design of all Boeing commercial airplanes, including a short-notice implementation for the new

767. With one fewer crewmember, Boeing engineers focused on a flight deck design that would

reduce crew workload, simplify older piloting functions, and enhance flight deck efficiency.

Then, as now, the navigation function was based on the IRS position and used ground-based navaids

(e.g., DMEs, VORs, localizers) to refine the IRS position and correct for IRS drift. A navigation

database (NDB) was included in the FMC’s memory and contained approximately 100 kilobytes of

data consisting of navaids, airways, approach procedures, and airports. The NDB allowed flight

crews to easily enter flight plans from takeoff to landing and make real-time route changes in

response to air traffic control (ATC) clearances. The FMC also provided guidance to the flight plan

route using the lateral navigation (LNAV) and vertical navigation (VNAV) functions. Initially, the

FMC was equipped with LNAV only. VNAV was a new challenge and required a significant effort on

the part of Boeing and Sperry (now Honeywell) engineers to make the vertical guidance component

operational. (32)

1980 to 1995 – Honeywell Flight

Management System 1 and

Fully Integrated Avionics

Honeywell describe the development of the same Flight Management System from their perspective

in a 2014 article “The Evolution of Flight Management”. (33)

“The year: 1980. The mission: develop a new digital avionics system for pilots to plan and

automatically fly a 3-dimensional flight trajectory optimized to provide the most efficient route

possible. Success would have a number of industry-changing benefits:

.Crew workload would be safely reduced to the point where air transport crew size could be

reduced from 3 to 2

. Aircraft position would be automatically calculated and would be more accurate than past

systems

. Full flight trajectories would be flown automatically

. The system would understand the unique aerodynamic characteristics of the air frame and the

engines so that it could minimize fuel burn or minimize time, or strike a pilot-defined balance

between the two.

It was a tall order, to be sure. The engineers at Sperry Flight Systems (a Honeywell legacy company)

embarked upon this challenge with two initial customers; Boeing and Airbus. The Boeing target

platforms were the 757 and the 767, while for Airbus it was the A310.

Providing solutions

The new system, dubbed the “Flight Management System,” or FMS, became a major

undertaking. The hardware platform included a Honeywell-build digital processor card (the SDP-

175), and this processor became the execution engine for the biggest software development program

the company had ever undertaken.

A new user interface was required to allow the entry and display of FMS alphanumeric data, and the

solution was the Control and Display Unit (CDU); the first true computer terminal in an air

transport aircraft. The CDU proved to be such a benefit that later versions were modified to allow

other avionics systems to connect to the CDU and use its data entry and display capabilities, and the

CDU was then renamed “Multifunction Control and Display Unit,” or MCDU. The MCDU went

from a monochrome display to colour on the A320 program. (33)

Understanding new technology

As complicated as the FMS was, its capabilities can be summarized into four functions:

. Flight Planning – defining where the airplane needs to fly

. Navigation – figuring out where the airplane is, along with its velocity

. Guidance – looking at where the airplane is supposed to be (flight plan), then using the

current aircraft position and velocity to control the airplane to the flight plan

. Performance – calculate the optimum trajectory for the aircraft to fly and provide predictions

for all the way points in the flight plan

The FMS included two databases: a Navigation Database and a Performance Database. The

Navigation Database contained detailed information for possible flight plan way points, airports,

departure and arrival procedures, and radio navigation aids, or “navaids.” The Performance

Database was actually two databases: the aerodynamic model of the air frame and the engine model

that gave detailed performance characteristics of the propulsion system.(33)

The addition of a comprehensive navigational database would turn out to be an additional tool in the

BHUAP arsenal. This would occur after 1995 when flight systems began to calculate their own flight

paths independently of the pilots, who only needed to check the FMS generated flight route and either

accept or amend it.

The mixing algorithm used each position solution to minimize the position error that is inherent in each individual position calculations, and thereby yielded an aircraft position solution that was more accurate than either radio or inertial position alone. In addition, it didn’t require any crew involvement. The FMS even automatically determined the best navaids to use and tuned them automatically. (33)

Details can be found in patent US6473675B2 (34) “Aircraft communication frequency nomination”, described as “an aviation signal nominating device includes a position receiving component that receives position data indicating a position of the aircraft, an aviation signal receiving component that receives a plurality of aviation signals associated with an aviation facility, each aviation signal having a prescribed frequency, and a nominating component that nominates at least one but not all of the plurality of aviation signals as a nominated aviation signal likely to be of interest to a pilot based on the position of the aircraft.”

The original ‘mission’ to develop a new digital avionics system to plan and automatically fly a 3- dimensional flight trajectory was the necessary foundation upon which the BHUAP could be constructed. The last major element still missing was the ability to navigate accurately enough to automatically land a CIVIL aircraft. This had already been accomplished by Boeing and Honeywell in the Dark Star UAV using military technology.

In 1987, Honeywell developed the first integrated Inertial Reference and Global Positioning System in order to conduct testing of autoland systems for NASA. A Honeywell-equipped NASA Boeing 737 performed the first GPS guided automatic landing proving that DGPS landings were possible. In the fall of 1990, Honeywell and NASA made 34 Category III landings using the Honeywell IRS/DGPS integrated landing system.” (35)

The test aircraft here used an Inertial Reference System containing the QRS11 Gyrochip.

Improving operations

The FMS navigation function provided a major operational improvement to the crew. The function

performed an automatic calculation of aircraft position by first using ground-based radio navaids to

calculate a radio position, then mixing this position with the aircraft position calculated by the

Inertial Reference System. The mixing algorithm used each position solution to minimize the position error that is inherent in each individual position calculations, and thereby yielded an aircraft position solution that was more accurate than either radio or inertial position alone. In addition, it didn’t require any crew involvement. The FMS even automatically determined the best navaids to use and tuned them automatically. (33)

Details can be found in patent US6473675B2 (34) “Aircraft communication frequency nomination”, described as “an aviation signal nominating device includes a position receiving component that receives position data indicating a position of the aircraft, an aviation signal receiving component that receives a plurality of aviation signals associated with an aviation facility, each aviation signal having a prescribed frequency, and a nominating component that nominates at least one but not all of the plurality of aviation signals as a nominated aviation signal likely to be of interest to a pilot based on the position of the aircraft.”

Certification and continued evolution

The initial FMS programs were certified in 1984. The FMS became a baseline system for all new air

transport aircraft and was retrofitted on a number of platforms over time. The system also migrated

to the business jet market. In the late 1980s, the need to move data between the FMS and the

ground was satisfied with ACARS (Aircraft Communication Addressing and Reporting

System). The airline operations center could now upload flight plans, along with wind and weather

data, to the FMS. . (33) The original ‘mission’ to develop a new digital avionics system to plan and automatically fly a 3- dimensional flight trajectory was the necessary foundation upon which the BHUAP could be constructed. The last major element still missing was the ability to navigate accurately enough to automatically land a CIVIL aircraft. This had already been accomplished by Boeing and Honeywell in the Dark Star UAV using military technology.

1990 – Honeywell perfects

GPS Autoland System

George Lewison comments on the 1996 issue of Avionics Magazine: “Honeywell has for years been

extremely interested in navigation utilizing the Global Positioning Navigation satellites. In the early

1980s Honeywell began development of a GPS receiver autonomous integrity monitoring algorithm

called (RAIM). This Honeywell-developed algorithm allows for the automatic detection and exclusion

of faulty satellite data from the GPS navigation solution without requirement for action by the crew. In 1987, Honeywell developed the first integrated Inertial Reference and Global Positioning System in order to conduct testing of autoland systems for NASA. A Honeywell-equipped NASA Boeing 737 performed the first GPS guided automatic landing proving that DGPS landings were possible. In the fall of 1990, Honeywell and NASA made 34 Category III landings using the Honeywell IRS/DGPS integrated landing system.” (35)

The test aircraft here used an Inertial Reference System containing the QRS11 Gyrochip.

1991 - The QRS11 Gyrochip

The QRS11 Gyrochip is a single-axis analogue solid-state quartz rate sensor. It’s simply an output

device that when voltage is applied, it will output the axis spatial acceleration the sensor detects as a

DC voltage, to be interpreted by a program, and translated into real time acceleration. Further

processing and monitoring over time can thus calculate the direction and speed at which the sensor is

travelling.

Systron-Donner explains: “The QRS11 is a compact, lightweight design, that features Quartz MEMS

technology providing a solid-state gyro offering virtually unlimited life. The QRS11’s combination of

high performance and long life makes it well suited for OEM’s and system integrators designing cost

effective, high performance systems.

The QRS11 requires only DC voltage inputs to provide reliable, extremely accurate angular rate

measurements with the benefit of no moving parts. With a hermetically sealed sensing element, the

QRS11 has provided reliable performance in aircraft, missile and space systems across many

demanding application environments.” (36)

The QRS11 Gyrochip was classified as military grade hardware which Honeywell and Boeing

(and many others) used in the ballistic missile and UAV navigation systems. Essentially QRS11

falls under the Missile Technology Control Regime and any export license granted to Boeing is

subject to: http://www.armscontrol.org/documents/mtcr (Category II Items 9, 10, 11) all of which

are under the Wassenaar Arrangement (37) of which Category 7 – Navigation and Avionics

pertains to the QRS11.

Early Honeywell avionics systems may have used the QRS11 in the Air Data Inertial Reference Unit

and the Secondary Attitude Air Data Reference Unit through their legacy company Systron Donner,

before GPS became accurate enough for use in the USA (June 2000) and for transcontinental flight.

The B777-200 uses an advanced ring-laser gyro in the Air Data Inertial Reference Unit and the

Secondary Attitude Air Data Reference Unit. It was not likely that the QRS11 was used in the B777-

2H6ER.

As DGPS and ring-laser gyro technology has advanced, the QRS11 Gyrochip is no longer considered

(since 2002) an essential item for the BHUAP. Prior to 2002 however it does indicate the inclusion of

a military-grade inertial reference system into a civil aircraft, for example it was retrofitted along with the Honeywell Digital Flight Data Acquisition Unit (38) to B737, B747, B757 and B767 aircraft,

the Parts Manufacturer Approval being received on the 25th June, 2001. Whilst the Flight Air Data

Unit was essentially a system for the black-boxes, it does put the QRS11 at the scene where

aircraft without the QRS11 in the ADIRU could be ‘upgraded’ and so make better use of the

Honeywell AIMS-1 BHUAP software already programmed into it as per the 1970 patents,

giving aircraft a means of accurate navigation for remote control flight.

1992 Preserving America’s Military

Advantage Through Dual-Use Technology

In the late 1980’s and early 1990’s, the Department of Defense was becoming increasingly aware that

US defense technology was no longer superior to the technology available in the commercial sector.

In a report to The White house in 1992 the Department of Defence made the following observations:

“…These new threats, if anything, increase the need for fast, flexible mobile forces equipped with the

most advanced weapons systems.

Technology is the key. Since World War II, U.S. military superiority has been based on our

technological advantage, as was plainly demonstrated in the Persian Gulf War. Technology will be

even more important in the uncertain and unstable environment we now face. To maintain its

technological advantage, the Department of Defence (DoD) must break down the barriers created

over the last 30 years between the defence and civilian sectors. Because of DoD's over reliance on

military specifications and because of the crush of a needlessly cumbersome procurement system,

many commercial firms refuse to do business with the Department of Defense altogether, and those

that do often wall off their defense production. DoD, as a result, has become reliant on an

increasingly segregated defence industrial base.” (39)

1993 The Technology

Reinvestment Project (T.R.P)

The T.R.P was unveiled by President Clinton in early 1993. The T.R.P awarded matching funds to

industry-led projects, selected purely on the basis of merit, to develop new dual-use technologies that

met defense needs. “The program's success to date is encouraging. A key to its success is the

emphasis on partnerships: the TRP has created unprecedented linkages for technology collaboration

and business partnership among defense and commercial companies, small and large firms, and

universities and laboratories. A second emphasis is cost-sharing. This cost-share ensures industries

commitment to the project and lays the foundation for industry to assume the total cost of production

development.”

“Since October 1992 the Institute for Defence Analyses has assisted the Advanced Research Projects

Agency (ARPA) with economic advice and recommendations regarding the Technology Reinvestment

Project (TRP) under the task entitled "The Economic Impacts of Technology Investments." The

purpose of the TRP is to promote integration of the commercial and military industrial bases to

improve the affordability of weapons and systems while also contributing to the commercial

competitiveness of U.S. industry through dual-use technology investments.” (40)

The mission of the T.R.P was to give the Department of Defense greater access to affordable, leading edge

technology by leveraging commercial know-how, investments and markets for military benefit.

T.R.P co-funded projects were of two types, the first being those that leveraged commercial technology

to meet defense needs and the second were projects termed ‘Transitioning Defense Technology’. The

second type of project promoted the transitioning of defense technologies back to commercial applications, making the technology more affordable and accessible to the military (such as

Honeywell selling Air Data Inertial Reference Unit containing the military grade Q.R.S 11).

As both Boeing and Honeywell were actively researching and producing UAV technology for the

Department of Defence it stands to reason that the BHUAP hardware and software came from these

programs. Both Boeing and Honeywell are not in the business of wasting money developing civil and

military hardware independently, especially when the relaxing of Dual-Use technology laws permitted

them to on-sell co-funded military technology to the commercial sector.

To be specific, the cost of the hardware and software routines developed for DoD programs such as

Dark Star (which was initially rejected by DARPA), could legally be recouped by including such

hardware and software in future aircraft and avionics systems.

This in itself was not BHUAP. That came later when the technology was exploited. However it does

provide a legitimate pathway that such BHUAP technology could pass into civil aircraft systems.

One such way was a 1995 competition announced on 21st October 1994. $415 million in matching

funds would go towards 12 dual-use focus areas. Two of these areas were:

. Microelectromechanical systems (MEMS) applications – Demonstration and insertion of

MEMS technology into defence and commercial applications (eg. inertial sensors)

. Affordable controls technologies – development of affordable, advanced digital electronics

and control technologies for enhanced military systems and industrial automation”

Clearly the Honeywell DGPS ADIRU augmented by the QRS11 fits the first category and

development of the full-flight from take-off to landing Honeywell AIMS-2 (covered in the next two

sub-sections) fits the bill for the second.

Coinciding with this were new 1994 FAA Minimum Aviation System Performance Standards

governing Required Navigational Performance of BOTH civil and military aircraft. Military aircraft

were not equipped to use DGPS and could not integrate into the civil aviation network or ILS

(Instrument Landing Systems) easily, and did not meet the new FAA standards. Civil aircraft could

not be used by the airforce to land on military airstrips in the reciprocal spirit of dual-use technology

as the ILS (Instrument Landing Systems) used by the military were different from those in the civil

sector.

The spin-off from DoD funding both the QRS11 equipped ADIRU and the DGPS augmented JPALS

(Joint Precision Approach Landing System), was that military aircraft could navigate and land in civil

airspace as now required by FAA introduced law, the cost of which was supplemented by Rockwell

Collins developing the JPALS and Boeing-Honeywell providing both civil and military aircraft with

QRS11 augmented ADIRU navigation including built-in D.G.P.S.

Boeing and Honeywell had a close relationship with the Department of Defense where for 40 years

prior they had jointly developed space, missile and unmanned aerial vehicle navigation and flight

control systems, mostly programmed in Ada-95. Boeing and Honeywell’s intention was to reuse the

intellectual property they had developed over decades rather than start something completely new and

from scratch, which makes perfect and legitimate sense from a corporate and financial point of view.

The regulatory conditions were right for military accessible remote-flight hardware and software

systems to find their way into civil aircraft.

1995 Honeywell’s Differential

GPS Satellite Landing System

George Lewison comments on the 1996 issue of Avionics Magazine: “In January of 1995, Honeywell

and Pelorus Navigation Systems Inc. of Calgary, Canada, joined forces to develop and manufacture a

Differential GPS (DGPS) Ground Station to be called the Satellite Landing System. The ground

station equipment is available in two configurations, the SLS-1000 and the SLS- 2000. Both systems

are comprised of three major subsystems: 1) Ground Reference Station 2) Remote Satellite

Measurement Units 3) VHF Data Link Transmitter.

The Teaming of Honeywell and Pelorus Navigation Systems of Canada was a good choice as Pelorus

had an extensive background in installation and training for approach aid technology. With this type

of background, the Honeywell team participated in Boeing’s Category III-b flight test evaluation

program in July and August of 1995. NASA supplied the 757 aircraft and flight test facility. Boeing

supplied the pilots, ground crew, maintenance, flight test personnel and performed the aircraft

modifications for the flight tests.

The flight tests were accomplished at NASA’s Wallops Island, Virginia, flight test facility. A total of

75 Category III-b automatic landings were accomplished during this phase of flight testing. The

Honeywell DGPS landing system replaced the standard ILS instrument landing system for these

test flights. The DGPS landing system provided equivalent lateral and vertical guidance signals to the

aircraft’s autopilot. The autopilot used the DGPS to guide the aircraft to a landing and then

continued to use the DGPS signals to provide lateral guidance to keep the aircraft cantered on the

runway during roll out.

Preliminary performance data of these flight tests showed that the Honeywell DGPS landing system

achieved the predicted system accuracy of one to two meters. The analysis of these results have been

used to help create the requirements for the impending certification of the DGPS precision landing

system.” (35)

1995 – Honeywell Flight

Management System 2 and

Fully Integrated Avionics

In the 1990s, the global positioning system (GPS) prompted further modification to the navigation

function, which provided even greater position accuracy. This accuracy could enable closer aircraft

spacing in oceanic airspace, which would allow the flying of more efficient flight plans. The FMS

used ACARS data link via satellite to send position information to Air Traffic Control (ATC) and

ATC would send clearances back to the aircraft. This capability, called FANS (Future Area

Navigation System), is a baseline function on most long haul aircraft today.

Honeywell writes in their article “The Evolution of Flight Management” (33) “The transition from

MCDU (Multifunction Control Display Unit) textual flight planning to graphical flight planning over

the last decade was a big one. Pilots make flight plan changes on the cockpit map display using a

cursor control device. This has been a very well-received human factors improvement.

In the late 1980's and 1990's, the airline industry requested the capability of direct routing from one

location to another, without the need to follow airways based upon ground-based navaids. Modern

FMS equipped with a multi-sensor navigation algorithm for airplane position determination using

VOR, DME, localizer, and IRS data made this possible, and RNAV was transformed from concept to

operational reality. (35)

But oceanic operations and flight over remote areas — where multi-sensor updating of the FMC

could not occur with accuracy better than the drift of IRS systems — made RNAV operations difficult.

Operations in these areas of the world were increasing during the 1990's, and there was pressure on

avionics suppliers, airplane manufacturers, and regulatory agencies to find a way to support precise

navigation in remote and oceanic areas. As a result, the concept of a future air navigation system

(FANS) was conceived in the early 1990's (see AERO second-quarter 1998).

Subsequently, Boeing and Honeywell introduced the first FANS 1-capable FMC. At the heart of the

system was a new, more capable FMC that implemented several new operations:

. Airline operational communications — Digital communication of data (data link) such as

text messaging, weather data, and flight plans directly from the airline operations facility to

the FMC.

. Controller-pilot data link communications — Digital communication between ATC and the

airplane in the form of predefined messages.

. Automatic dependent surveillance — Information about position and intent generated from

an ATC request.

. Global positioning system (GPS) — Incorporation of satellite navigation functions in the

FMS for the primary means of navigation.

. Air traffic services facilities notification — ATC communication protocol initialization.

. RNP — A statement of the navigation performance necessary for operation within a defined

airspace.

. Required time of arrival — Enablement of airplane performance adjustments to meet

specified waypoints at set times, when possible.” (35)

The digital data communications link provides an airline operator to directly upload new software and

alternate flight plans directly to the Flight Control Computer from a remotely based facility (such as

Boeing HQ or an AWACS).

“Although each feature was individually significant, the three primary enablers for FANS operations

were RNP, GPS, and data link. RNP defined the confines of the lateral route, and the FMC provided

guidance to reliably remain on the route centreline. The FMC’s RNP function also provided alerting

to the flight crew when this containment might not be assured. GPS was originally a military

navigation sensor that was allowed for commercial use with some limitations. Integrated as the

primary FMC position update sensor, GPS provided exceptionally precise position accuracy

compared to ground-based sensors and enabled the FMC’s capability for precise navigation and path

tracking. GPS remains the primary sensor for the current generation FMCs. Data link provided a

reliable method of digital communication between the airplane and the air traffic controller. A

comprehensive list of preformatted messages was implemented to provide for efficient traffic

separation referred to as controller-pilot data link communications.

Concurrent with the FANS 1 FMC, Alaska Airlines teamed with Boeing, Smiths Aerospace (now GE

Aviation), and the FAA to develop procedures that would provide reliable access to airports that are

surrounded by difficult terrain. By virtue of the surrounding rough terrain, the Juneau, Alaska,

airport became the prime candidate for the certification effort. Because the approach to runway (RW)

26 was the most challenging air corridor to Juneau, it was selected as the most rigorous test to prove

the real performance capability of RNP (see fig. 3).

In 1995, Alaska Airlines successfully demonstrated its ability to safely fly airplanes to RW 26 using

RNP and soon began commercial operations using RNP, which was a first for commercial aviation.

Figure 3: Juneau, Alaska: Site of initial RNP certification efforts

RNP enabled an approach to runway 26 and access to Juneau that in some weather conditions was not otherwise practical.

The concept of a reliable and repeatable defined path with containment limits was not new. Early

conceptual work was done at the Massachusetts Institute of Technology in the 1970's, but the modern

FMC, with its position accuracy and guidance algorithms, made reliable path maintenance practical.

The first demonstration of the FMC’s terminal area precision came at Eagle, Colorado, in the mid-

1980's. A team comprising American Airlines, the FAA, and Sperry (now Honeywell) applied RNP-like

principles to approach and departure procedures to the terrain-challenged runway. Following

simulator trials, the procedures were successfully flown into Eagle and subsequently approved by the

FAA. The result: reliable approach and departure procedures that provide improved access to Eagle.

Although Eagle demonstrated the FMC’s capability to execute precisely designed terminal area

procedures, in the mid-1980's, it would take another 10 years until RNP equipment was available for

airline operators. The FMC’s navigation position accuracy enhanced with GPS and lateral and

vertical guidance algorithms, the development of the vertical error budget, and additions to crew

alerting enabled RNP and its future applications.“ (35)

1995 to 2000 – The Aircraft

Information Management System:

Honeywell AIMS-1

The original AIMS system was the first integrated modular avionics system for the air transport sector

and is still the most highly integrated one, consolidating the processing for 10 different aircraft

systems. Inside the cabinets, the units are broadly differentiated by module type–such as core

processing and I/O.

AIMS-1 core processing modules (CPMs) come in four basic flavors. Each type has a common set of

processing resources–processor, instruction memory, bus interfaces and power–and some unique

circuit card assemblies (CCAs), or plug-in modules. The CPMs include:

. CPM/Basic, which does not have a special-function CCA.

. CPM/Comm, with interfaces to the airplane fibre optic LAN (local area network), the A717

interface to the flight data recorder, and an RS-422 interface to the quick access recorder.

. CPM/GG (graphic generator), with the core processor and a graphic generation CCA, which

connects to the flight deck display units.

. And CPM/ACMF (aircraft condition monitoring function), with an additional memory CCA

that stores ACMF data.

Because the AIMS architecture uses generic building blocks, a need existed for multiple software

applications to be able to share common hardware resources, without corrupting each other’s data.

This led to the development of Honeywell’s Apex operating system–with its time and space

partitioning–which became the foundation for the ARINC 653 operating system spec. Under Apex, for

example, the central maintenance function (Level D of DO-178B), flight deck communications (Level

C) and DCG (Level A) can share the same processing hardware yet still be developed and verified

independently [developed here means ‘produced’].

Another achievement was deferred maintenance through fault tolerance. Boeing required a continued,

10-day dispatch rate of up to 99.9 percent in the face of any failure, assuming a full-up system at the

beginning of that period, recalls Gust Tsikalas, Honeywell product line director. With AIMS this was

performed largely in software, by carrying extra copies of the applications, rather than many different

processor modules. Honeywell’s deterministic SAFEBus backplane technology allowed the company

to prove that "another copy of a software application could be running and ready to go, so that, [if

needed, it] could come on line without a hiccup," Tsikalas says. A backup software function can

transition into a primary function within two backplane clock cycles, a matter of nanoseconds. (35)

With the patented inclusion of an AIMS system called the Unauthorized Flight Detector, a backup

Flight Management System we have called the BHUAP (or Boeing have called the Boeing

Uninterruptable Autopilot) could be brought on line whereby control is removed from the Primary

Flight Control Computers used by the pilot to control the aircraft. Control would then by default pass

to the Autopilot via an external, uplinked control source. The uplinked control source could be either

a remote pilot or an uploaded back-up flight route. This is documented in both Boeing and

Honeywell’s Autoflight patents.

to be continued....next

No comments:

Post a Comment